New carrier particles improve inhalation drugs

A research team led by Professor Regina Scherlie├¤ at the Institute of Pharmacy at Kiel University (CAU) has developed new carrier particles for powder inhalers that could significantly increase the effectiveness of inhalation drugs. The study, published in Communications Materials, shows that the geometry of the particles has a decisive influence on the release of the active ingredient. A special design, the so-called “Pharmacone”, outperformed all other tested variants.

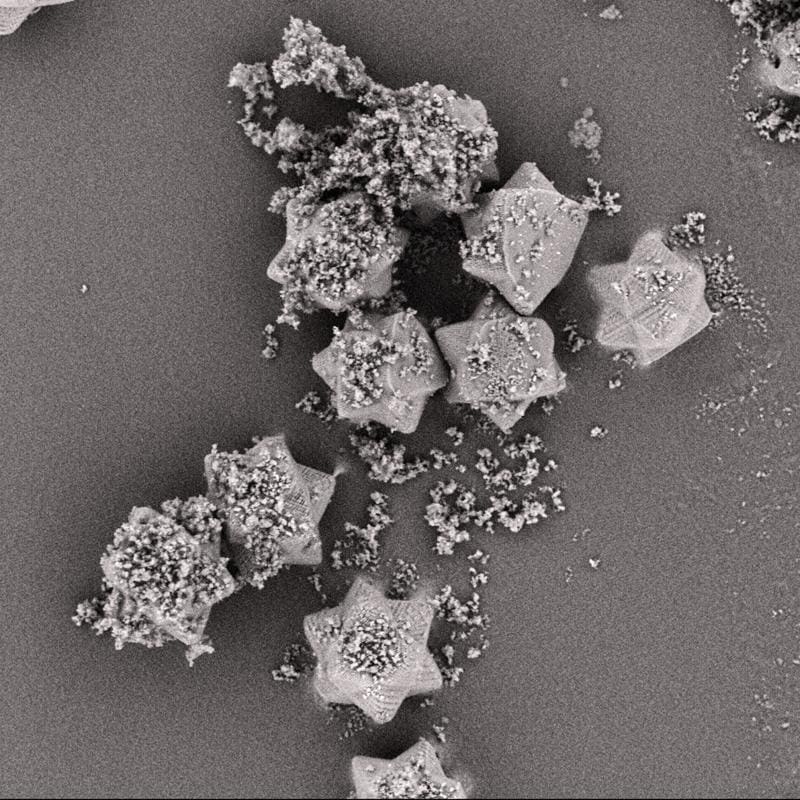

The tiny carrier particles, barely thicker than a hair, were produced using a high-precision 3D printing process called two-photon polymerization. This process, which was optimized in cooperation with the Karlsruhe Institute of Technology (KIT), enables the production of millions of identical particles with a resolution in the nanometer range. Thanks to a new printing technique, up to 49 structures could be produced at the same time, which significantly speeds up production. Four different particle designs were tested for the study, one of which was produced in three variants with different surface roughness. The particles were mixed with a model active ingredient, as is common in real inhalation preparations.

The tests showed that the shape of the carrier particles largely determines how much active ingredient is released when inhaled and reaches the lungs. The Pharmacone design, which is reminiscent of a small star with several tips, showed the best results: The proportion of the active ingredient in the respirable size of less than five micrometers was four times higher than in the next best variant. The researchers attribute this to the special geometry, which causes more frequent collisions and rotations of the particles due to its tips, which makes it easier for the active ingredient to detach. The surface roughness, on the other hand, had no influence on the release.

Although the particles are currently still model structures for basic research and not suitable for inhalation, the researchers see great potential for pharmaceutical development. In the future, such precisely designed, biodegradable carrier particles could be used directly in powder inhalers. The ability to optimize the behavior of drugs through targeted design at the micrometer level opens up new avenues for the development of more efficient inhalation drugs.

The study was carried out in cooperation with KIT, where the high-precision printing process was further developed. Financial support came from the German Research Foundation (DFG), the Carl Zeiss Foundation and the Helmholtz Program “Materials Systems Engineering”.

Original Paper:

Melvin Wostry (2025) et al: “Aerodynamic Performance of Tailored Microparticles as Carriers in Dry Powder Inhaler Formulations Made by Multi-Focus Multi-Photon 3D Laser Printing”, Nature Communications Materials, DOI: 10.1038/s43246-025-00913-0

Editor: X-Press Journalistenb├╝ro GbR

Gender Notice. The personal designations used in this text always refer equally to female, male and diverse persons. Double/triple naming and gendered designations are used for better readability. ected.