Gas chromatography: Mobile system detects food fraud on site

In the future, a mobile gas chromatography sensor system will identify incorrectly declared products directly on site. To this end, three Fraunhofer Institutes are developing an inexpensive, easy-to-use device that enables a quick evaluation even by non-experts. It analyzes volatile organic compounds and detects manipulations such as dyed rapeseed oil as olive oil. The technology addresses growing fraud cases in the food industry and in the recycling sector.

Food fraud has been on the rise for years. High demand, strong price pressure and complex supply chains create ideal conditions for incorrect labelling. The dizziness can lead to significant health risks if harmful ingredients are used. Previous detections require time-consuming, expensive laboratory tests. In addition, laboratory-based analysis systems need specialist personnel to operate and evaluate data. Fraunhofer researchers want to remedy this situation. In the Fraunhofer PREPARE project PUMMEL, research teams from the Fraunhofer Institutes for Photonic Microsystems IPMS, for Molecular Biology and Applied Ecology IME and for Process Engineering and Packaging IVV combine their core competencies in the fields of gas chromatography measurement methods, sensor development and chemical sensor technology. The result is a mobile gas chromatography sensor system for the rapid on-site detection of volatile organic compounds. These chemical compounds are characteristic of a certain composition or health hazard and are associated with changes in product properties. The detection of such compounds is of great importance in many areas. These include food quality and safety, medical markers, civil security, agriculture and the chemical industry.

Two industry-relevant applications

The need for cost-effective, fast and robust on-site measurement technology that delivers immediate results is high. The system is not arbitrary, but versatile due to its modifiability. In the PUMMEL project, the researchers are concentrating on two industry-relevant applications as examples. On the one hand, the identification of counterfeit olive oil, which is one of the top 10 most counterfeited foods. On the other hand, the identification of contaminated plastic recyclates that accumulate in packaging, for example. This is significant because the recycling rate will have reached a new high of almost 70 percent in 2025. To this end, the institutes are developing two application-specific demonstrators for the detection of volatile organic compounds.

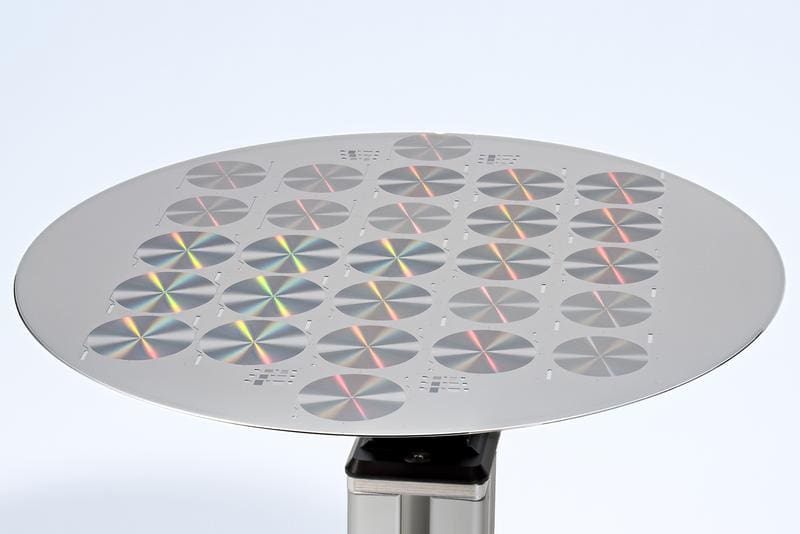

The mobile system, which will later be the size of a shoulder bag, consists of a silicon chip-based gas chromatography column, a detector or sensor, integrated sample preparation, control and evaluation electronics and an energy supply. Gas chromatography is an analytical method for the separation, identification and quantification of mixtures of substances, which is suitable for gaseous or undecomposed vaporizable substances. In this process, a sample is first transported through the column with the help of a carrier gas, which is etched into a silicon chip that can be heated and cooled quickly. In the column, the gas molecules interact with the polymer-coated inner walls. Depending on their affinity, the volatile organic compounds react with the inner layer of the column, and the mixture of substances is separated. At the end of the chip-based column, a detector measures the substances sorted according to their molecular type, resulting in a gas chromatogram with peaks from which the composition of the mixture can be deduced. The evaluation of the measurement data is carried out by Fraunhofer IME. In the case of olive oil, the aim is to determine parameters such as the country of origin, age and degree of purity.

First tests successfully completed

Current tests with a conventional column with a length of three meters show a reliable separation performance of the volatile organic compounds and enable the evaluation of the samples. Columns in conventional, expensive laboratory gas chromatographs are often over 30 meters long and have a better separation performance, which is not required for the quality assessment of many foods. Among other things, the Fraunhofer researchers are faced with the challenge of designing miniaturized columns that are able to sufficiently separate the volatile organic compounds in a food-specific manner.

With the system, the researchers are addressing laypeople such as the bottler and the incoming goods inspector, who can easily operate the device without technical know-how after a short briefing. The system’s components can be customized for specific applications, making it suitable for quality control in many applications, such as the evaluation of recycled plastics. Together with industry, the institutes are happy to implement tailor-made application developments.

The researchers will present some of the results of the project from March 24 to 27, 2026 at the Analytica trade fair in Munich at the Fraunhofer joint booth in Hall 3, Booth 312.

Editor: X-Press Journalistenb├╝ro GbR

Gender Notice. The personal designations used in this text always refer equally to female, male and diverse persons. Double/triple naming and gendered designations are used for better readability. ected.